- Industrial Area, Sharjah, UAE

- info@nibrasfurniture.com

- +971 50 5257397

We have built a bespoke manufacturing plant to deliver client specific furniture and fixtures to the highest standard

We are a top-tier industrial furniture manufacturer based in the UAE, with a proven track record of producing high-quality and durable furniture products for industrial settings. Our expertise, commitment to excellence, and customer-centric approach have established us as a leader in the industry.

Nibras Furniture is the go-to choice for businesses throughout the UAE seeking exceptional furniture products. Our reputation for excellence has earned the trust of companies of all sizes and industries

We have built a bespoke manufacturing plant to deliver client specific furniture and fixtures to the highest standard

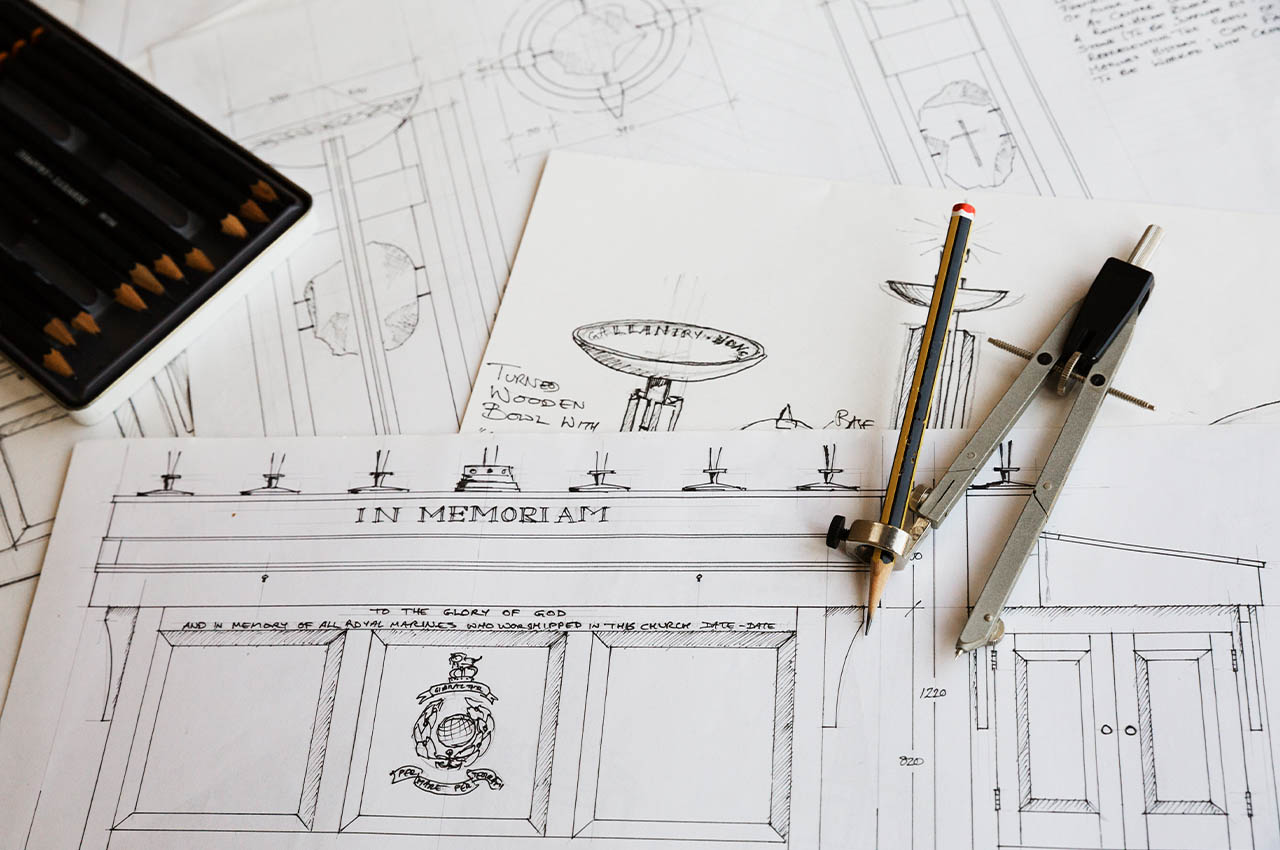

Furniture manufacturing begins with designing the product, taking into consideration the style, functionality, and materials to be used.

The materials used in furniture manufacturing vary depending on the design and style of the furniture. Common materials include wood, metal, plastic, and fabric

Once the design and materials have been selected, the manufacturing process involves cutting the materials to the required size and shape.

After the materials have been cut, they are joined together using various methods such as gluing, nailing, or screwing.

The furniture is then sanded to smooth out any rough edges and prepared for finishing. Finishing can involve staining, painting, or varnishing the furniture.

For furniture that requires fabric, such as sofas and chairs, upholstery is the process of covering the furniture with fabric and stuffing to create a comfortable seat

Before the furniture is shipped to retailers or customers, it goes through a quality control process to ensure that it meets the standards set by the manufacturer.

Depending on the furniture design, some furniture may require assembly by the customer. Manufacturers typically provide assembly instructions and tools to make the process as easy as possible.

Once the furniture has been manufactured and passed quality control, it is packaged and shipped to retailers or directly to customers.

Customer service desks & reception counters

Office and Home

Malls and Offices

Home and Office

Home and Office

Office Generic

We are a top-tier industrial furniture manufacturer based in the UAE, with a proven track record of producing high-quality and durable furniture products for industrial settings. Our expertise, commitment to excellence, and customer-centric approach have established us as a leader in the industry.

Overall, this 3-step consulting process help us improve their manufacturing process, increase productivity and efficiency, and produce high-quality products that meet customer needs and expectations.

The first step is to assess the current state of the furniture manufacturing process. This includes reviewing the manufacturing equipment, production methods, workforce skills, and product quality. The assessment should identify any areas for improvement and opportunities for optimization.

Based on the assessment, the next step is to recommend specific changes and improvements to the furniture manufacturing process. This may include upgrading equipment, implementing new production methods, providing training to the workforce, or improving quality control measures. The recommendations should be tailored to the specific needs and goals of the furniture manufacturer.

The final step is to implement the recommended changes and improvements to the furniture manufacturing process. This may involve purchasing new equipment, reorganizing the production line, providing training to the workforce, or implementing new quality control measures. The implementation process should be carefully planned and executed to ensure a smooth transition and minimize disruptions to production.